Manufacture of brass lamps and chandeliers

Brass in artisanal lighting

Brass is an alloy of copper and zinc that is used by Aldo Bernardi to create high quality handcrafted chandeliers. This material is chosen above all for its ductility, which allows the creation of intricate and detailed shapes.

The malleability of brass allows for smooth or richly textured surfaces, adapting to different design requirements. Furthermore, brass is known for its durability, retaining its distinctive beauty even over the years. Brass is therefore an extremely versatile material that plays a key role in Aldo Bernardi's craftsmanship and can be used for lighting all environments, indoors and outdoors.

The unique characteristics of brass are a perfect match for Aldo Bernardi's craftsmanship philosophy, which aims to create high quality products following ancient artisan traditions. Each lighting product made of brass is the result of a meticulous process that combines experience, passion and a touch of modernity.

Brass lamps and chandeliers: art and functionality

Brass is a material that narrates a story of art and functionality, of tradition and innovation, of light and warmth. Aldo Bernardi's brass lamps and chandeliers are the result of skilful craftsmanship, transforming this metal alloy into works of art with a timeless style.

Every brass lamp and chandelier is a light housing that encloses an infinite world of light, capable of creating unique and warm atmospheres. The timeless elegance and the golden colour of brass lend refinement and style to the products, making them suitable for any type of environment.

Processing brass: from raw material to work of art

The crafting of brass is an art that requires time, dedication and passion, characteristics that go beyond mere industrial production.

This is the case of Aldo Bernardi's brass products, a collection of chandeliers that tell a story of tradition and innovation. Each piece is the result of a handcrafted process that follows the ancient techniques of casting and plate turning, at the same time with an eye to contemporary design.

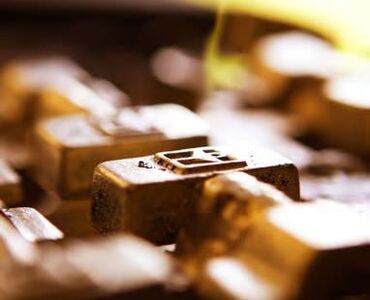

The process begins with the selection of the best brass alloy, a compound of copper and zinc that gives the metal its characteristic ductility and brilliance. The alloy is then melted in a special furnace, at a temperature of around 1000 degrees Celsius, until it becomes a glowing liquid ready to be shaped.

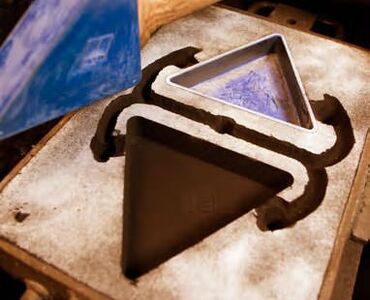

The melted brass is poured into moulds, made of metal or sand, depending on the desired shape and size. Once cooled, the brass is removed from the moulds and cleaned of impurities.

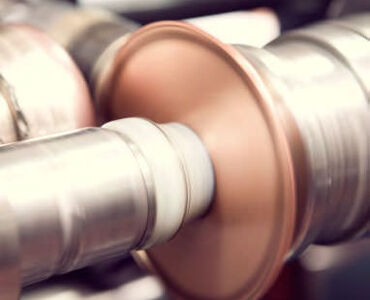

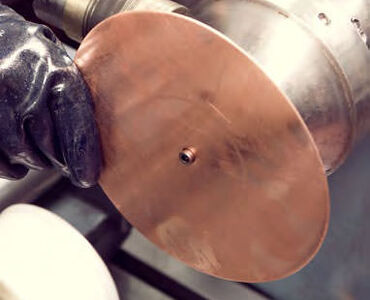

Brass plate turning

The manufacturing process of the lamp straight out of the mould can vary depending on the type of product. In the case of Aldo Bernardi's brass chandeliers, one of the most typical processes is plate turning. This is an ancient technique that consists of deforming a sheet of metal to obtain a rounded shape. In practice, a brass disc is rotated at high speed on a lathe and pressed against a metal form that gives it the desired shape.

The result is a slab-turned product distinguished by its exceptional surface finish, which gives it a glossy, shiny appearance.

The crafting of brass does not stop there. Each piece is then finished with specific treatments that enhance its colour and texture. Some examples are oxidation, patination, brushing and varnishing.

Finally, the pieces are assembled together to form the final work. Each chandelier is unique and unrepeatable, the result of the creativity and skill of the craftsmen who made it.

The brass antiquing process for our lamps

Aldo Bernardi's lamps are the result of meticulous attention to detail, especially in the antiquing process. Aldo Bernardi faithfully reproduces the natural oxidation process of brass, using a manual technique that speeds up the process, but does not alter the phases.

The process of antiquing brass is a craftsmanship honed over the years, celebrating the beauty of controlled ageing and the patina that brass acquires over time. Each Aldo Bernardi lamp is created with a commitment to maintaining the authenticity and charm of time gone by, guaranteeing a product that encapsulates the elegance and uniqueness of craftsmanship that has been painstakingly cared for down to the smallest detail.

The finished lamp is not painted, to allow the antiquing process to continue naturally, depending on the weathering of the area in which it is located. The only final treatment is a beeswax protection, which insulates the chandelier, even if only temporarily, from the influence of the weather.

In environments with a high salinity level, the artefact, not being painted, may be subject to a more noticeable oxidation process. Consequently, in such locations, regular treatment with beeswax is essential.

Aldo Bernardi's brass lamps

Each brass lamp by Aldo Bernardi is an object imbued with Italian passion and craftsmanship.

From classic brass pendants that create a warm and welcoming atmosphere, to wall lamps that decorate walls with style and refinement, to chandeliers that give rooms a touch of majesty and brilliance.

Each brass lamp by Aldo Bernardi is designed to embody the perfect balance between tradition and modernity, representing the essence of Italian craftsmanship.